Physical Address

23,24,25 & 26, 2nd Floor, Software Technology Park India, Opp: Garware Stadium,MIDC, Chikalthana, Aurangabad, Maharashtra – 431001 India

Physical Address

23,24,25 & 26, 2nd Floor, Software Technology Park India, Opp: Garware Stadium,MIDC, Chikalthana, Aurangabad, Maharashtra – 431001 India

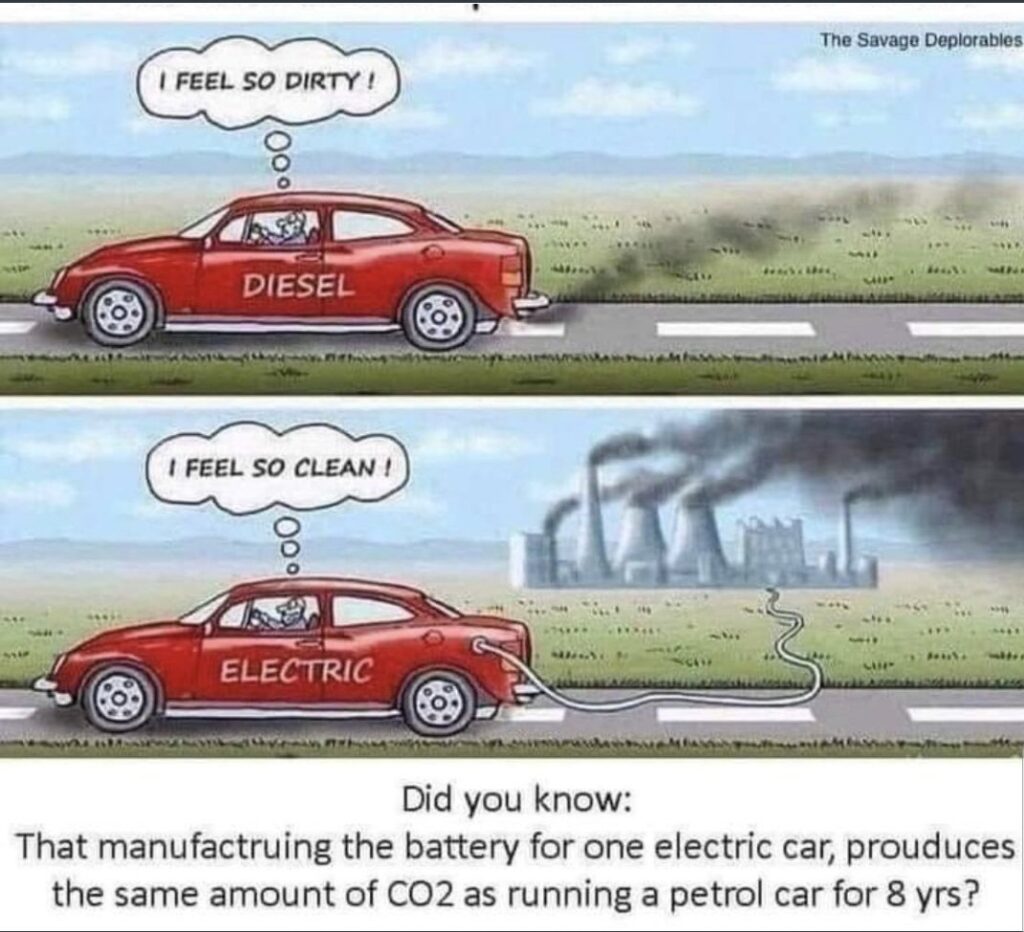

CLAIM

Manufacturing the battery for one electric car produces the same amount of CO2 as running a petrol car for 8 years.

FACT

Production of an electric car battery emits CO2 equivalent to running a petrol car for 1 or 2 years, not 8 years as claimed. Also, the CO2 emission from electric car battery production can be swiftly and easily offset once the electric car starts running without tailpipe emissions.

WHAT THEY SAY

The battery of the electric car has often been targeted to claim its inefficiency compared to petrol or diesel driven cars. It has been claimed that the manufacturing of the electric battery leads to such a huge amount of CO2 emission that the overall purpose of the electric car to reduce dependence on or phase out fossil fuel-driven cars is not served well. Multiple social media posts seem to be doing the rounds claiming the same. We come across a particular creative/cartoon claiming that ‘manufacturing the battery for one electric car produces the same amount of CO2 as running a petrol car for 8 years.’

WHAT WE FOUND

Electric vehicles normally use a type of rechargeable battery known as the Lithium-ion (Li-ion) battery as a power source unlike the fossil fuel-based power source in conventional vehicles to operate an internal combustion engine. The Lithium-ion (Li-ion) battery has a higher energy density than typical lead-acid or nickel-cadmium rechargeable batteries. This helps battery manufacturers to save space and reduce the overall size of the battery pack.

It has become a popular power source for clean technologies like electric vehicles because of its charging capabilities, and ability to store more energy in a relatively smaller space. While this kind of battery is crucial in the global effort to phase out fossil fuel-driven vehicles that are known to be significant emitters of CO2 and other greenhouse gases, concerns have been raised about the manufacturing process of the electric vehicle batteries with claims that the process itself is a major polluter of the environment.

“Yes, it is true that the production of lithium-ion batteries and their components used very often in Electric Vehicles (EVs) is associated with the emission of GHGs. Extraction from mines and processing metals like lithium, cobalt and nickel required for the batteries use electricity that is usually of thermal/coal origin resulting in the emission of CO2 and other GHGs. Intense heating required for the production of batteries is also sourced from mainly coal-fired power. This is a weakness of the technology and production processes involved in making EVs at present,” said climate scientist and expert, Dr Partha Jyoti Das.

Scientific findings and research have however found that EVs emit less GHGs in comparison to conventional fossil fuel-powered vehicles even if the battery production emission of the EVs is taken into consideration.

“But even then, EVs are generally more emission efficient than conventional vehicles (CVs) that are driven by internal combustion engines that use fossil fuels like petrol, diesel or natural gas. Studies done in Europe and America indicate that EVs emit 40% less GHG compared to petrol or diesel-based vehicles even when you account for GHG emission during the battery production process,” Das further added in this regard.

How much CO2 is emitted by manufacturing Electric Vehicle batteries?

MIT says, ‘it depends exactly where and how the battery is made—but when it comes to clean technologies like electric cars and solar power, even the dirtiest batteries emit less CO2 than using no battery at all’.

Further, according to MIT, for manufacturing an 80 kWh lithium-ion battery, CO2 emissions would range between 2400 kg (almost two and a half metric tons) and 16,000 kg (16 metric tons). One ton of CO2 is emitted by a typical gas-powered car in about 2,500 miles of driving.

“An electric vehicle running on [electricity generated with] coal has the fuel economy equivalent in the order of about 50 to 60 miles per gallon equivalent,” says David Keith, a professor at the MIT Sloan School of Management. “So the dirtiest electric vehicle looks something like our best gasoline vehicles that are available today.”

According to Politifact, who consulted Zeke Hausfather, a climate scientist and director of climate and energy at the Breakthrough Institute, “If the battery were made in Asia, manufacturing it would produce 7,500 kg of carbon dioxide, or the equivalent of driving a gasoline-powered sedan for 2.4 years — but still nowhere near the eight years claimed in the Facebook post.”

Battery manufacturing life-cycle emissions debt quickly paid off

According to an analysis by the International Council for Clean Transportation (ICCT), ‘an electric vehicle’s higher emissions during the manufacturing stage are paid off after only 2 years compared to driving an average conventional vehicle, a time frame that drops to about one and a half years if the car is charged using renewable energy.’

The report further noted that approximately half of a battery’s emissions come from electricity used in the manufacturing process. ‘Battery manufacturing emissions appear to be of similar magnitude to the manufacturing of an average internal combustion engine vehicle, or approximately a quarter of an electric car’s lifetime emissions,’ the report further said.

EV Battery manufacturing getting cleaner

Ongoing research and innovation in EV-related technologies promise to make the entire lifecycle of production, use and maintenance of EVs including batteries much cleaner than at present.

“This makes one optimistic about the increasing effectiveness of EVs as a means of climate change mitigation through decarbonisation of the transport sector. With the proliferation of renewables like wind and solar in every sector, the use of coal-fired electricity in battery production is about to get reduced rapidly leading to the coveted carbon neutral status very soon. Increasing recycling rates of batteries is also leading to a reduction in battery-related emissions,” Dr Das added.

Life cycle assessment of GHG footprint of EVs versus CVs that take into account emission during all processes and phases of manufacturing, maintenance, use and efficiency, has indicated that even at present EVs are relatively cleaners than CVs.

Comments are closed.

[…] Also Read : CO2 emitted in making an EV battery isn’t equal to driving a petrol car for 8 years […]